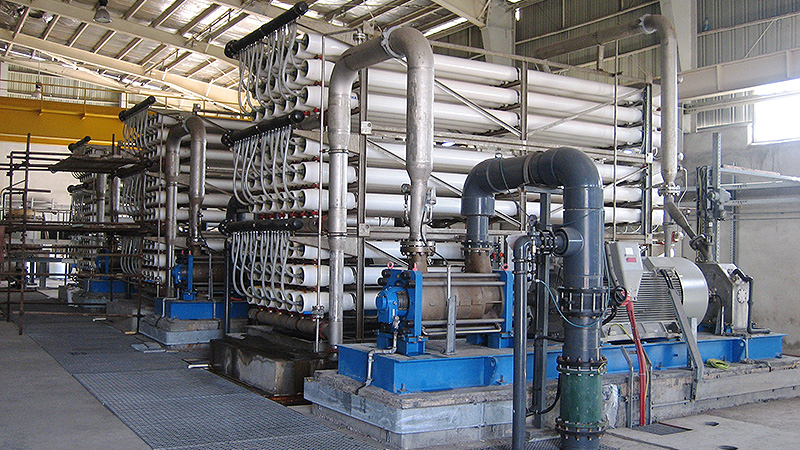

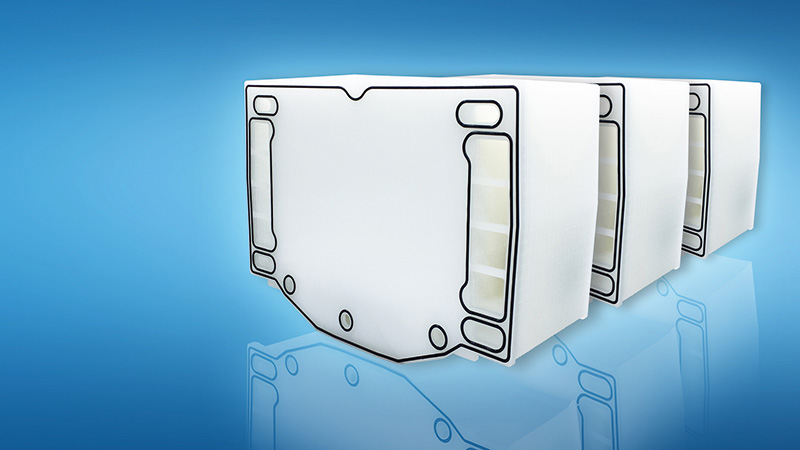

Desalination using sea and brackish water reverse osmosis membrane technology (SWRO and BWRO) has emerged as a viable option for the development of new regional water supplies. Reverse Osmosis (RO) is another widely used industrial water purification technology. Effective mineral and salt removal transform previously unusable waters into a high-purity resource for industrial process applications. RO technology employs the use of a plastic membrane to remove salt from seawater. RO is the process of switching flow through a membrane from high salinity, or concentrate, the solution to high purity, or “permeate,” stream on the other side of the membrane.

As a result, a significant amount of energy that would otherwise be lost can be recovered. The pre-treatment that protects the membrane from organic fouling, mineral scaling, and chemical degradation is the most important factor in seawater desalination using reverse osmosis (RO). It includes all of the necessary treatment steps prior to the reverse osmosis plant. It determines plant lifetime and reduces chemical cleaning and membrane replacement. It has a direct impact on plant performance.

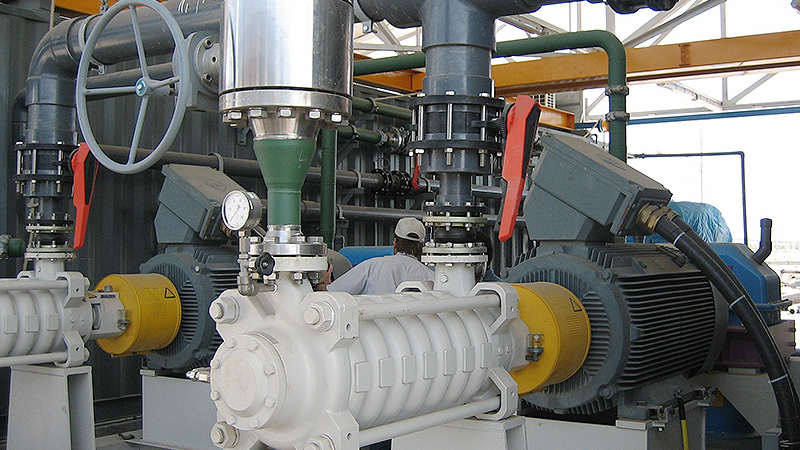

Before feeding water to the RO plant, NAHR-ALFAYHA uses conventional filtration or ultrafiltration (UF), dissolved air floatation (DAF), water softening or acidification, and disinfection. NAHR-ALFAYHA Reverse Osmosis (RO) systems provide high performance while minimizing life-cycle costs. Our pre-engineered systems enable quick delivery and are constructed with high-quality components tailored to the customer’s specific needs. They are assembled at the customer’s location under the supervision of NAHR-highly ALFAYHA’s qualified engineers and delivered to the customer fully operational with all filters, membranes, pumps, piping, controls, and automation. Additionally, NAHR-ALFAYHA offers a complete line of membrane treatment chemicals to improve membrane performance once the equipment is installed at your site.